The values lying outside the control limits show that the process is out of control. Start studying OSCM 306 Questions.

6 3 1 What Are Control Charts (source:pinterest.com)

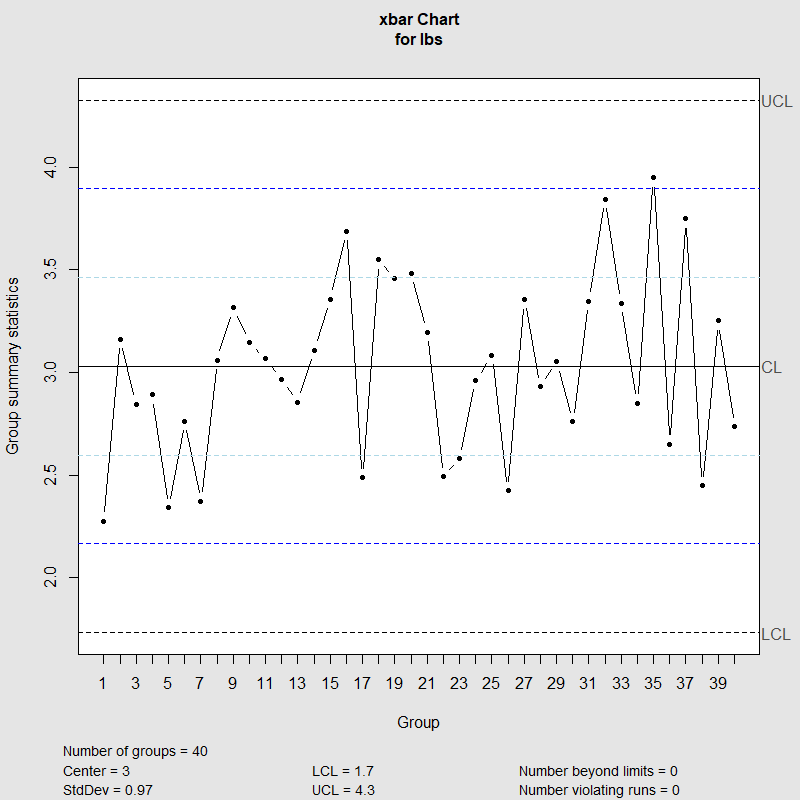

This type of chart graphs the means or averages of a set of samples plotted in order to monitor the mean of a variable for example the length of steel rods the weight of bags of compound the intensity of laser beams etc.

A control chart used to monitor the process mean is the:. The CUSUM and EWMA charts differ from the individuals charts in that they take into account the information of previous. Control charts are used to routinely monitor quality. Control charts have two general uses in an improvement project.

By comparing current data to these lines you can draw conclusions about whether the. In constructing this chart samples of process outputs are taken at regular intervals the means of each set of samples are calculated and graphed onto the X bar control chart. A control chart is used to monitor a process mean by collecting sample means from that process on a regularly scheduled basis.

The horizontal or X axis on this chart will represent the mean value of the sample while the vertical or Y axis will represent time measured in hours days or weeks. Solution for A control chart used to monitor the process mean is known as O a. What are X Bar S Control Charts.

It weights observations in geometrically decreasing order so that the most recent observations contribute highly while the oldest observations contribute very little. These lines are determined from historical data. Spread of data E.

The X-bar chart is the most common control chart for monitoring the process mean. It is a time series graph with the process mean at center and the control limits on both sides of it. A less common although some might argue more powerful use of control charts is as an analysis tool.

Grant chart O e. This way you can easily see variation. Journal of Statistical Computation and Simulation.

Learn vocabulary terms and more with flashcards games and other study tools. Control charts are a great tool that you can use to determine if your process is under statistical control the level of variation inherent in the process and point you in the direction of the nature of the variation common cause or special. Control chart is a statistical tool used to monitor whether a process is in control or not.

These charts are used when the subgroups have large sample size and S chart provides better understanding of the spread of subgroup data than range. The range chart R-chart is most likely to detect a change in. The most common application is as a tool to monitor process stability and control.

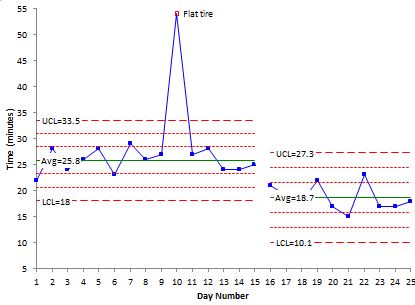

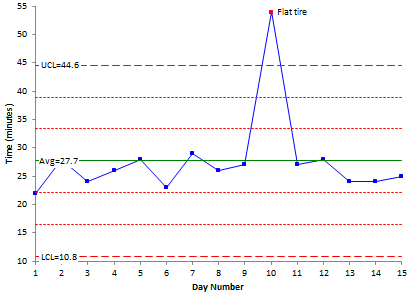

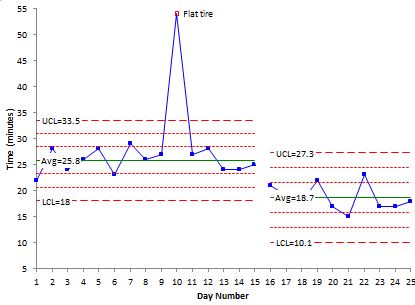

A c-chart is used to monitor the number of defectives in the output of a process. The CUSUM chart is useful for quickly detecting small shifts in the process mean. A control chart always has a central line for the average an upper line for the upper control limit and a lower line for the lower control limit.

The first referred to as a univariate control chart is a graphical display chart of one quality characteristic. The range chart R-chart is most likely to detect a change in. Control charts tell the operator when to do something and when to do nothing.

Control charts are a great tool to monitor your processes overtime. A control chart to monitor the process mean based on inspecting attributes using control limits of the traditional X-bar chart. The CUSUM chart is based on an established target mean and a reliable value for sigma.

X bar control chart. A c-chart is used for. The control chart is a graph used to study how a process changes over time.

Depending on the number of process characteristics to be monitored there are two basic types of control charts. Number of defects per unit 27. Other Control Charts for the Individuals Two additional control charts available for monitoring the process mean for individual observations are the cumulative sum CUSUM and exponentially weighted moving average EWMA charts.

The X-bar chart is useful for detecting large changes in the process mean. X Bar S charts often used control chart to examine the process mean and standard deviation over the time. The second referred to as a multivariate control chart is a.

A control chart used to monitor the process mean is the A. Solution for The control chart used to monitor the process mean is known as O a. Control chart is a real-time time-ordered graphical process feedback tool designed to tell an operator when significant changes have occurred in the manufacturing process.

The X-bar chart is usually used in Phase I monitoring when process control is being established. Number of defects per unit 27. Grant chart O c.

A control chart illustrates process behaviors by detecting changes in a process. A c-chart is used for. An exponentially weighted moving average EWMA chart is a type of control chart used to monitor small shifts in the process mean.

Data are plotted in time order. True A c-chart is used to monitor the number of defects per unit of a process output. Upper Control Limit Lower Control Limit.

Parts of a Control Chart UpperLower Warning Limits Some control charts will have upper and lower warning limits Calculate standard deviation STD of points used to determine mean Upper and lower warning limits calculated by multiplying the STD x 2 Add STD x 2 to mean. A control chart used to monitor the process mean is the A.

Lean Six Sigma Tools Understand The Purpose Of These Tools Lean Six Sigma Agile Project Management Agile Project Management Templates (source:pinterest.com)

Spc Statistical Process Control Statistical Process Control How To Apply Control (source:pinterest.com)

Control Chart A Key Tool For Ensuring Quality And Minimizing Variation Lucidchart Blog (source:pinterest.com)

The Purpose Of Control Charts (source:pinterest.com)

C Control Charts Bpi Consulting (source:pinterest.com)

Pareto Chart Goleansixsigma Com Chart Lean Six Sigma Infographic (source:pinterest.com)

Control Charts And Stability Analysis Chart Process Control Foreign Language Teaching (source:pinterest.com)

The Purpose Of Control Charts (source:pinterest.com)

Pin On Quality And Productivity Improvement Tutorials (source:pinterest.com)

Types Of The Control Chart With Example 7 Qc Tools Spc Chart Excel Templates Control (source:pinterest.com)

Conceptdraw Samples Business Processes Flow Charts Process Flow Chart Process Flow Chart Template Flow Chart (source:pinterest.com)

Quality Control Charts X Bar Chart R Chart And Process Capability Analysis By Roberto Salazar Towards Data Science (source:pinterest.com)

Tidak ada komentar:

Posting Komentar